Metalwork

Production is equipped with modern equipment, which allows you to perform metalworking tasks with a high degree of accuracy and quality in a fairly short time.

Foundry section

The work of the area consists of melting aluminum in a modern induction furnace and manufacturing parts on a casting machine under pressure in molds made specifically for certain tasks.

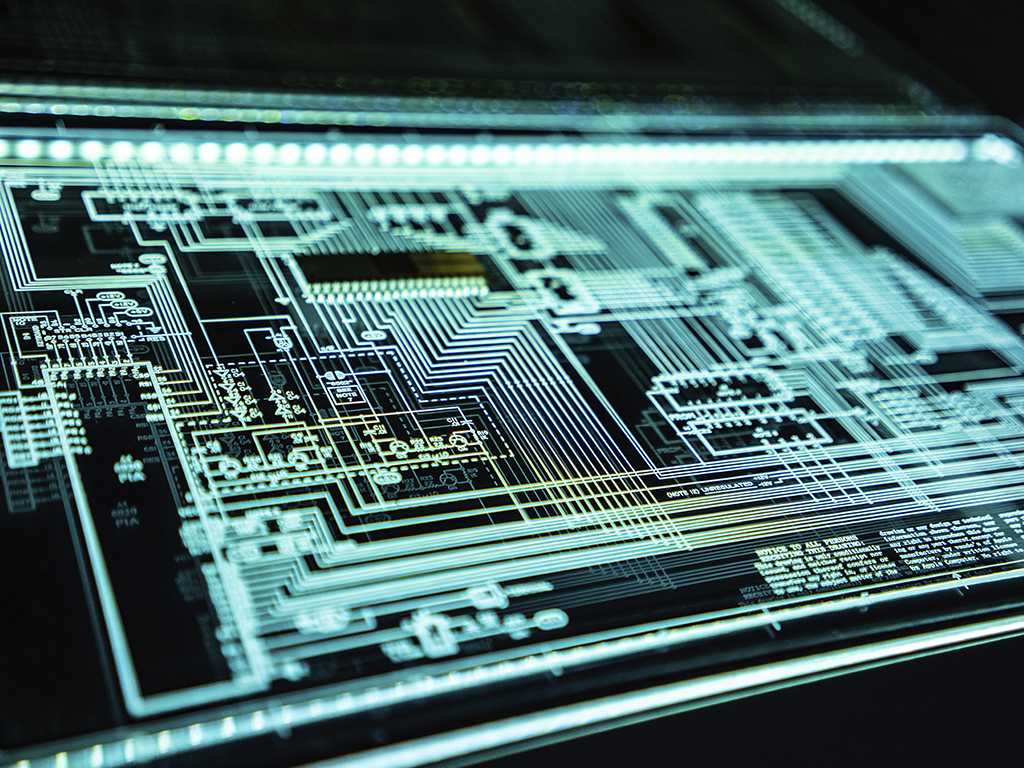

Laser cutting section

The work of the site is to cut and produce parts from sheet metal with high accuracy.

Cold stamping and bending section

Production of parts by the cold stamping method. The popularity of this processing is due to the low energy consumption of the process and the possibility of obtaining volumetric products of various configurations from flat parts. The presses used meet all the technological requirements, making it possible to obtain a finished product of the highest quality and low cost of parts in serial production, which has a positive effect on the price of the products offered.

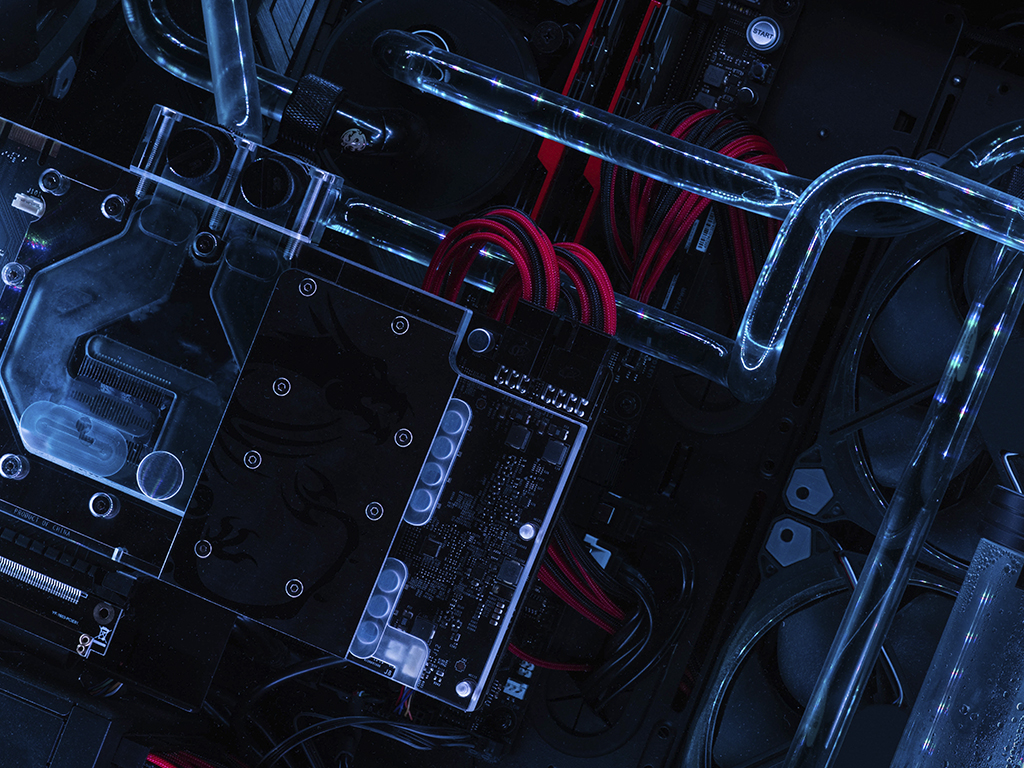

Automated machine section

Metal milling on professional and high-precision CNC equipment, as well as the production of molds for foundry and stamping equipment are carried out at the site.

Mechanical section

The main function of the mechanical section is to bring the products to the condition of suitable products, which is received by the customer. This area is used for deburring after milling, bringing the surfaces of the part to the required surface quality.